Conspectus Chalybis Inoxidabilis 430

SS430 est chalybs inoxidabilis ferriticus cuius resistentia corrosionis appropinquat chalybi inoxidabilis 304/304L. Haec qualitas non cito durescit per laborem et formari potest per operationes lenes extensionis, flexionis, vel tractionis. Haec qualitas adhibetur in variis applicationibus cosmeticis internis et externis ubi resistentia corrosionis maioris momenti est quam robur.SSGradus 430, comparatus cum plerisque chalybibus inoxidabilibus, male suturatur propter maiorem carbonis copiam et defectum elementorum stabilientium huius gradus, quod curationem caloris post suturam requirit ad resistentiam corrosionis et ductilitatem restituendam. Gradus stabilizati, ut...SS439 et 441 pro applicationibus chalybis ferritici inoxidabilis conglutinati considerandae sunt.

Specificatio Chalybis Inoxidabilis 430

| Nomen Producti | Spira Chalybis Inoxidabilis 430 | |

| Typus | Frigidum/Calidum laminatum | |

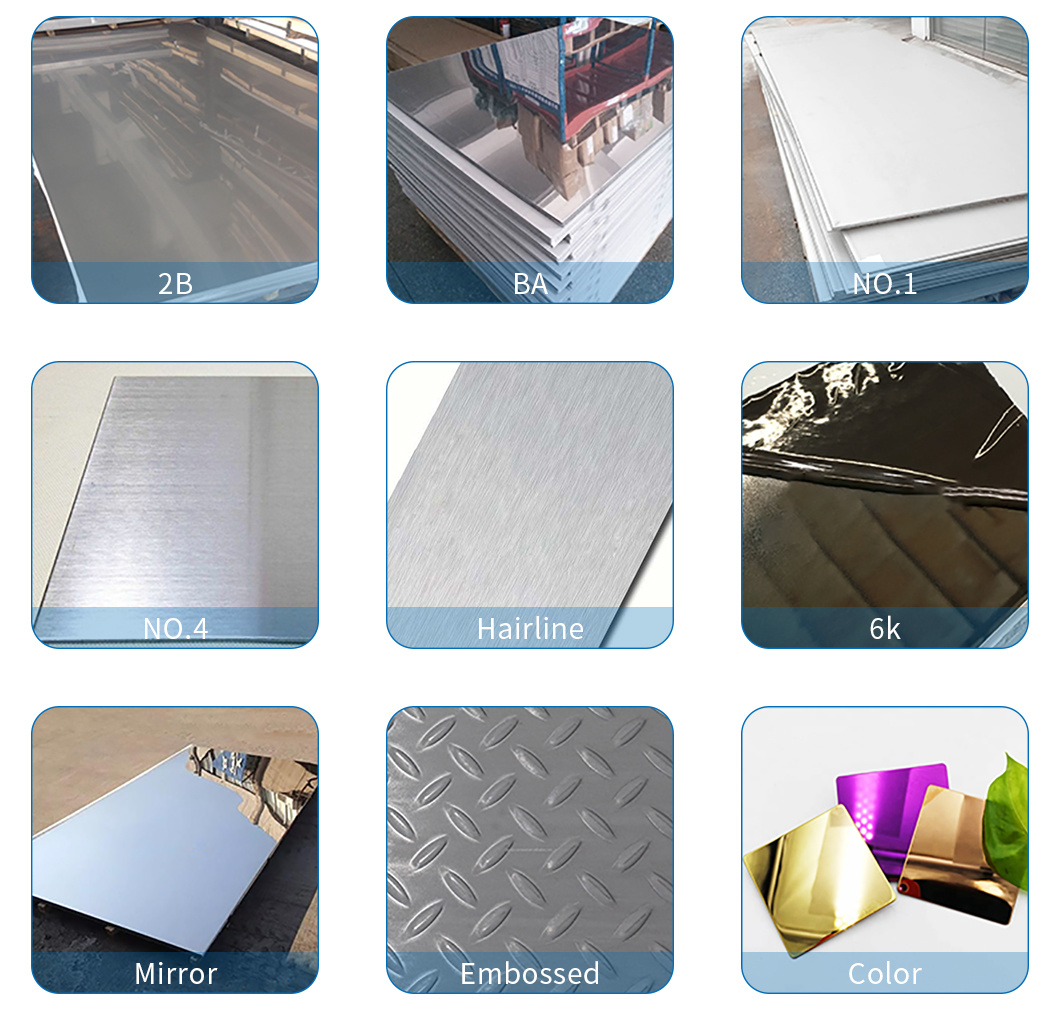

| Superficies | 2B 2D BA (Splendide Recoctum) No1 No3 No4 No5 No8 8K HL (Linea Capillorum) | |

| Gradus | 201 / 202 / 301 / 303 / 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 318 / 321 / 403 / 410 / 430 / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 / S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etc. | |

| Crassitudo | Frigide laminatum 0.1mm - 6mm Calido laminatum 2.5mm - 200mm | |

| Latitudo | 10mm - 2000mm | |

| Applicatio | Aedificatio, Chemica, Pharmaceutica et Biomedica, Petrochemica et Refinaria, Ambitus, Cibi Processus, Aviatio, Stercora Chemica, Cloacarum Eiectio, Desalinatio, Incineratura Vastorum etc. | |

| Officium Processus | Machinatio: Tornus / Fresatura / Planificatio / Perforatio / Terebratio / Trituratio / Sectio Rotarum Dentatarum / Machinatio CNC | |

| Deformatio processus: Flexio / Sectio / Volutio / Impressio / Soldatio / Fusio | ||

| Minimum Quotae Money (MOQ) | 1tonna. Exempla quoque accipere possumus. | |

| Tempus traditionis | Intra 10-15 dies laboris post acceptum depositum vel L/C | |

| Sarcinatio | Charta aquae impervia et lamina ferrea involuta. Sarcina navigabilis exportationis ordinaria. Apta omnibus generibus translationis, vel prout opus est. | |

Compositio Chemica et Proprietates Mechanicae 430

| ASTM A240/A240M (Designatio UNS) | S43000 |

| Compositio Chemica | |

| Chromium | 16-18% |

| Nickel (max.) | 0.750% |

| Carbonium (max.) | 0.120% |

| Manganum (max.) | 1.000% |

| Silicium (max.) | 1.000% |

| Sulphur (max.) | 0.030% |

| Phosphorus (max.) | 0.040% |

| Proprietates Mechanicae (recoctae) | |

| Tensio (min. psi) | sexaginta quinque milia |

| Reditus (min. psi) | Triginta milia |

| Elongatio (in 2″, min %) | 20 |

| Duritia (max Rb) | 89 |

-

201 304 Coloribus Obductum Ornatum Chalybe Inoxidabili...

-

201 Coil Frigide Laminatum Coil 202 Coil Chalybis Inoxidabilis

-

201 J1 J2 J3 Venditor Laminarum/Taeniarum Chalybis Inoxidabilis

-

Spira Chalybis Inoxidabilis 316 316Ti

-

Coil/Taenia Chalybis Inoxidabilis 430

-

Spiculum Chalybis Inoxidabilis Specularis 8K

-

Spira Chalybis Inoxidabilis 904 904L

-

Spira Chalybis Inoxidabilis Colorata

-

Spira Chalybis Inoxidabilis Duplex 2205 2507

-

Spira Chalybis Inoxidabilis Duplex

-

Spira Chalybis Inoxidabilis 316 Aurea Rosacea

-

Coagula/Taenia Chalybis Inoxidabilis SS202 in Promptu

-

Cochlea/Taenia Chalybis Inoxidabilis SUS316L