Conspectus

Laminae ferreae ad fistulas magni diametri fabricandas adhibentur, quae oleum et gas naturale transportant, etiam laminae ferreae tubularis appellatae. Nunc magis ac magis homines in mundo de conservatione naturae nostrae curant, nova energia pura, gas naturale, late per fistulas adhibetur. Hae laminae ferreae fistularum facultatem habent resistendi pressione alta, corrosioni atmosphaericae et temperaturis inferioribus. Classificatio API X120 a nobis oblata proprietates mechanicas altiores quam norma internationalis habuit.

Omnes Gradus Ferri Laminae Ferri Tubularis

| NORMA | GRADUS CHALYBIS |

| API 5L PSL1 / PSL2 | Gradus A, Gradus B X42, X46, X52, X56, X60, X65, X70, X80, X100, X120 L245, L290, L320, L360, L390, L415, L450, L485, L555 |

Proprietates Mechanicae laminae ferreae fistulae

| Gradus | Ratio puncti cessionis permissibilis | Robur Cedendi MPa (min) | Robur tensile MPa | Elongatio % (min) | |

| API 5L | EN 10208-2 | ||||

| API 5L Gradus B | L 245NB | ≤ 0.85 | 240 | 370 - 490 | 24 |

| API 5L X 42 | L 290NB | ≤ 0.85 | 290 | 420 - 540 | 23 |

| API 5L X 52 | L 360NB | ≤ 0.85 | 360 | 510 - 630 | |

| API 5L X 60 | L 415NB | ||||

| API 5L Gradus B | L 245MB | ≤ 0.85 | 240 | 370 - 490 | 24 |

| API 5L X 42 | L 290MB | ≤ 0.85 | 290 | 420-540 | 23 |

| API 5L X 52 | L 360MB | ≤ 0.85 | 360 | 510 - 630 | |

| API 5L X 60 | L 415MB | ||||

| API 5L X 65 | L 450MB | ≤ 0.85 | 440 | 560 - 710 | |

| API 5L X 70 | L 485MB | ≤ 0.85 | 480 | DC - DCCL | |

| API 5L X 80 | L 555MB | ≤ 0.90 | 555 | DCXXV - DCC | 20 |

Requisita Technica pro lamina ferrea fistularum

● Examen Valorum Duritudinis

● Examen ponderis deiecti (DWTT)

● Examen Ultrasonicum (UT)

● Experimentum impactus temperaturae humilis

● Volutio chalybis secundum normas fistularum API

Officia Addita

● Analysis Producti.

● Inspectionem a Tertia Parte ordinare.

● Simulatio curationis caloris post-soldaturam (PWHT).

● Experimentum temperaturae inferioris secundum postulata emptorum.

● Certificatum probationis molendini originalis sub EN 10204 FORMAT 3.1/3.2 emissum.

● Iaculatio et pictura, sectio et ferruminatio secundum desideria usoris finalis.

-

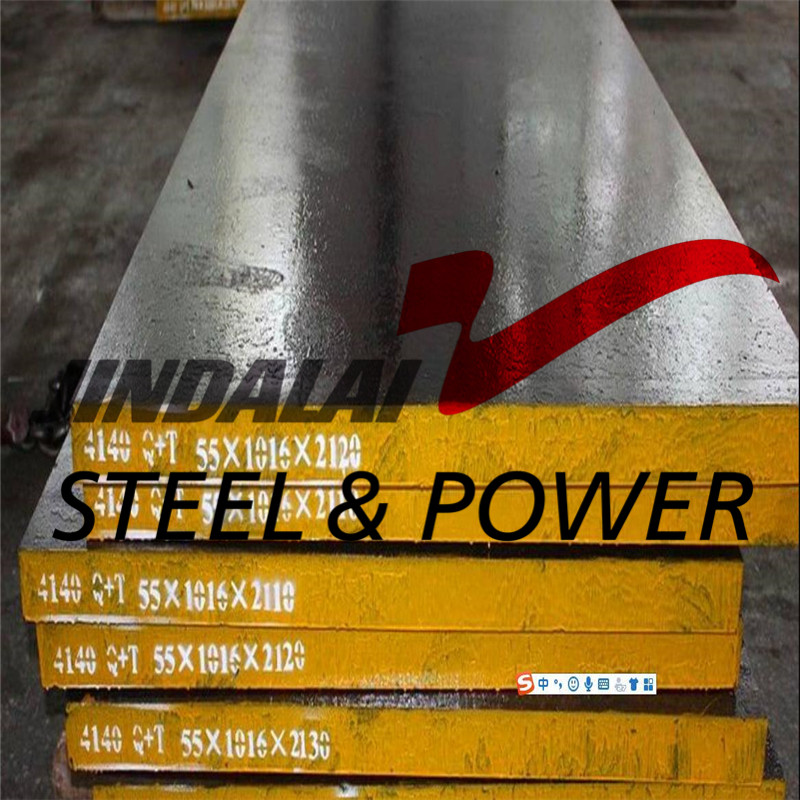

Lamina Chalybis Alloy 4140

-

Lamina ferrea navis 516 Gradus 60

-

A36 Fabrica Laminarum Chalybis Calidi Laminatarum

-

Laminae Ferreae Abrasioni Resistentes

-

Lamina Ferrea ASTM A36

-

Laminae Ferreae Corten ad Temperiem Exercendam ASTM A606-4

-

Tubus Chalybis Carbonis API5L / Tubus ERW

-

Tubus Chalybeus ASTM A53 Gradus A et B Tubus ERW

-

Tubus Ignis Aspersorii / Tubus ERW

-

Tubus Ferreus SSAW/Tubus Spiralis Sudurae

-

ASTM A53 Tubus Coniunctus Transversum Sonic Logging (CSL)

-

A106 Tubus Transversum Sonicae Diagraphiae Soldatus